steam boilers for cogeneration of steam and power

steam boilers

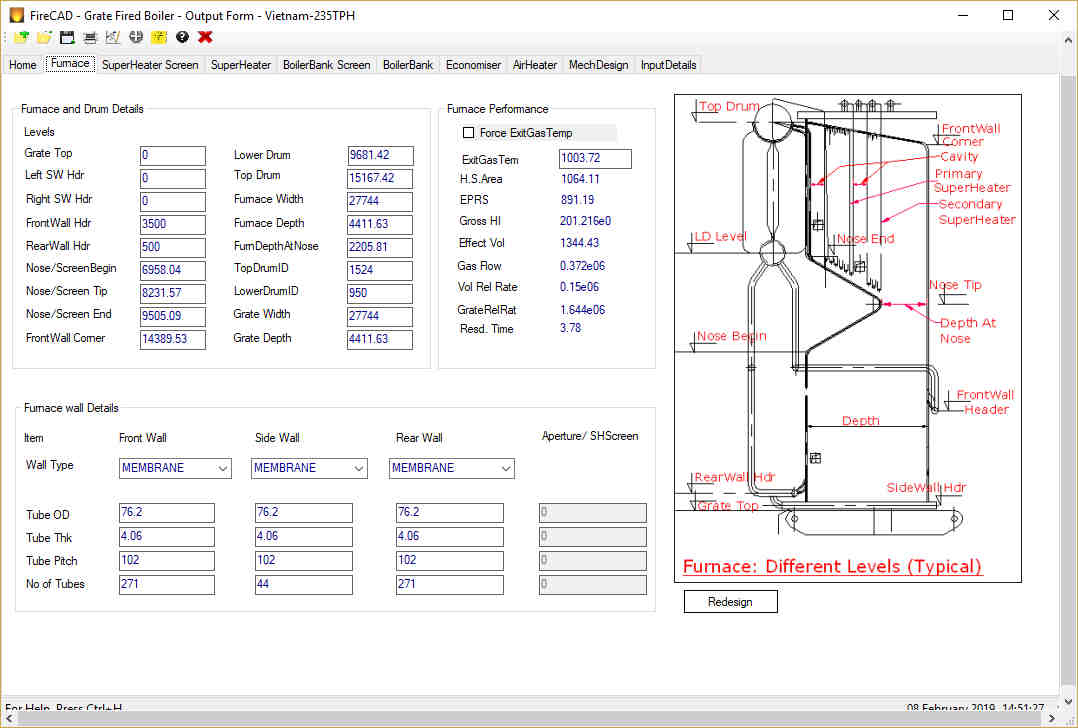

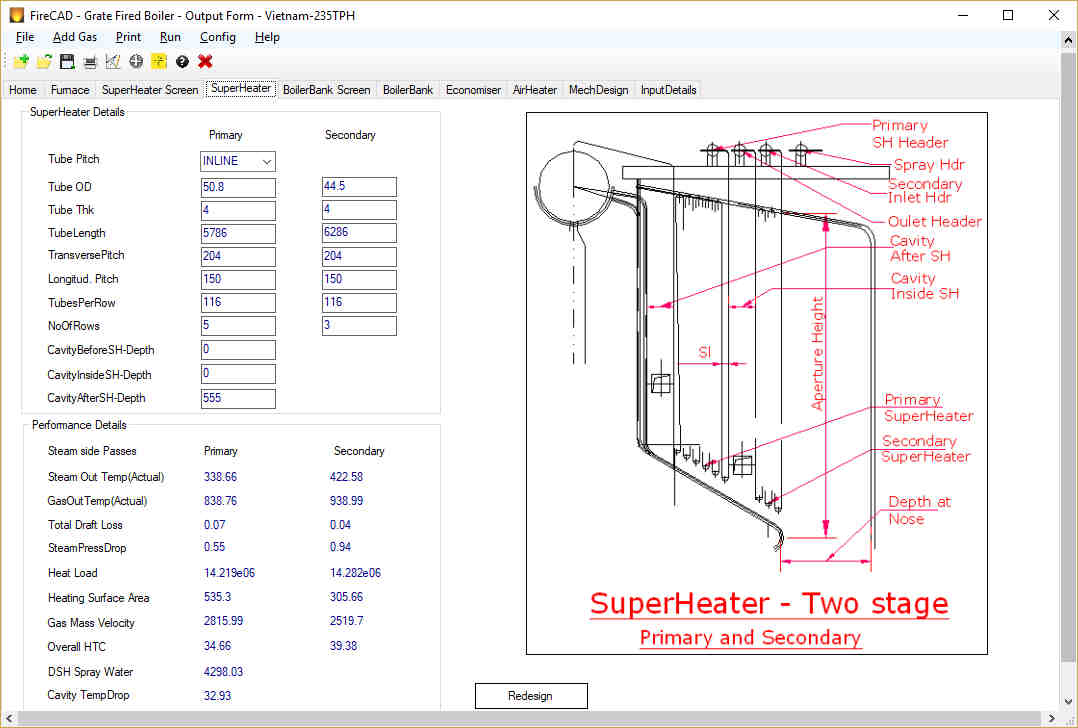

Travelling Grate Boilers

up to 250,000 Kg/hr, 125 bar & 540 degC

Fuels: Coal, Bagasse, Rice Husk, Biomass etc.

Fluidized Bed Combustion Boilers (AFBC or BFB)

up to 125,000 Kg/hr, 125 bar & 540 degC

Fuels: Coal, Lignite, Peat, Rice Husk, Biomass etc.

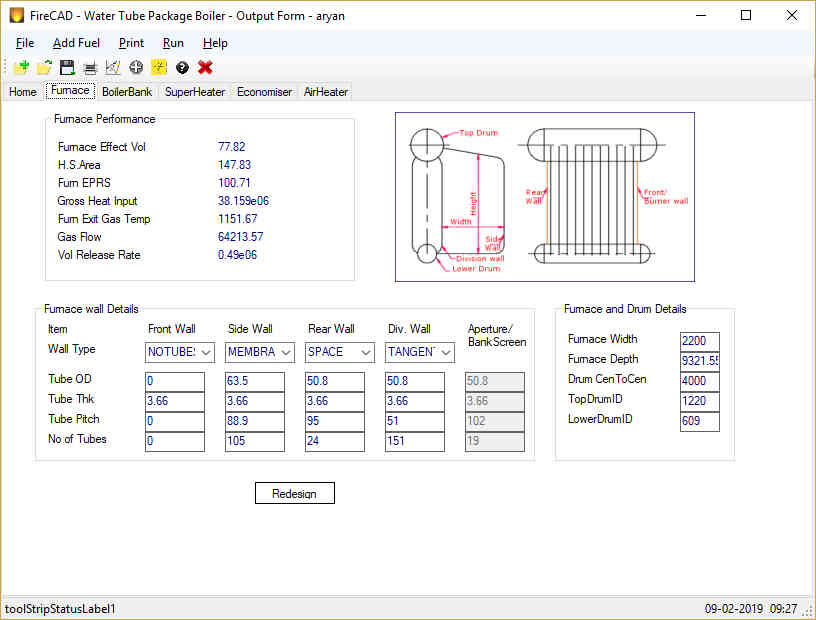

Package Boilers

Fire Tube and Water Tube : up to 250,000 Kg/hr

Fuels: Natural Gas/ Oil . Coal, Biomass

Heat Recovery Boilers

up to 150,000 Kg/hr

HRSG, Steel Plants, Engine exhaust ..etc

FireCAD advantage

FireCAD software for Boiler design

our latest projects

| S,No | Project Name | Boiler Rating |

|---|---|---|

| 1 | Baramati Agro Unit – 1 , India | 110,000 kg/hr, 87 bar , 520 degC

SUGAR PLANT: EXPANSION FROM 4200 TCD TO |

| 2 | Baramati Agro Unit – 2 , India | 130,000 kg/hr, 87 bar, 520 degC

SUGAR PLANT: EXPANSION FROM 7500 TCD TO |

| 3 | Martand Sweeteners Ltd , India | 700 TCD JAGGERY PLANT: 12 TPH @ 32Kg/Cm², 380° C DUMPING GRATE BOILER & 1 X 1.5 MW COGEN |

| 4 | SHIVSHAKTI SUGARS LTD, India | BIOMASS POWER PLANT: 36 TPH @ 87Kg/Cm², 520° C TRAVELLING GRATE BOILER WITH 1 X 5 MW COGEN FOR DISTILLERY UNIT. |

| 5 | Pramukh Steel Ltd, Uganda | 36,000 kg/hr, 67 Kg/Cm², 510 degC |

| 6 | Jyothi Sugars, India | 500 TCD KHANDSARI PLANT: EXPANSION FROM 300 TCD TO 500 TCD KHANDSARI PLANT. BOILER: 15TPH @ 32Kg/Cm², 380° C DUMPING GRATE BOILER WITH 1.2 MW COGEN. |

| 7 | Surya Bio-fuels, Jambia | FBC- COAL FIRED : 18 TPH AFBC @45Kg/Cm², 450° C & 1 X 2 MW COGEN |

| 8 | Arjun Sugars, India | 90,000 kg/hr, 87 Kg/Cm², 520degC |

| 9 | Govardhan Sugars, India | SLOP/SPENT WASH BOILER: 12 TPH, @ 45Kg/Cm², 410° C TRAVELLING GRATE BOILER WITH 1 X 1.5 MW COGEN |

| 10 | Shiruguppi Sugars, India | BIOMASS POWER PLANT: 65 TPH @ 87Kg/Cm², 515° C TRAVELLING GRATE BOILER WITH 1 X 12.1 MW COGEN. |

| 11 | Shiva Shakthi Sugars Hermes Distillery , India | BIOMASS POWER PLANT: 110 TPH @ 87Kg/Cm², 520° C TRAVELLING GRATE BOILER WITH 1 X 17 MW COGEN FOR DISTILLERY UNIT. |

| 12 | Vasundhara Green Bio Energy, India | BIOMASS POWER PLANT: 20 TPH @ 45Kg/Cm², 440° C TRAVELLING GRATE BOILER WITH 1 X 2.5 MW COGEN |

| 13 | Yadeshwar Agro Products Ltd, India | BIOMASS POWER PLANT: 90 TPH @ 72.5 Kg/Cm², 510° C TRAVELLING GRATE BOILER FOR SUGAR PLANT. |

| 14 | Venus Agro Fuels Pvt Ltd, India | 60 KLPD GRAIN BASED DISTILLERY: 60 KLPD DISTILLERY, 20 TPH @ 45, 440DegC AFBC BOILER WITH 1 X 2 MW COGEN |

| 15 | SHK Chemtech Industries, India | BIOMASS POWER PLANT: 35 TPH @ 67Kg/Cm², 450° C TRAVELLING GRATE BOILER WITH 1 X 4 MW COGEN |

| 16 | KIBOS SUGAR LTD, KENEYA | BIOMASS BASED POWER PLANT: 100 TPH @45Kg/Cm², 445°C TRAVELLING GRATE BOILER & 1 X 14 MW COGEN. |

| 17 | ECO FARM MOZAMBIQUE LIMITADA, MOZAMBIQUE, AFRICA |

400 TCD ORGANIC SUGAR PLANT: 20 TPH BOILER @45Kg/Cm², 450° C TRAVELLING GRATE BOILER WITH COMPLETE SUGAR PLANT EQUIPMENT. |

| 18 | MAGNUM ENGINEERED PRODUCT CORPORATION, USA |

COMPONENT OF SUGAR MACHINERY AND EQUIPMENT. |